Simscape Fluids

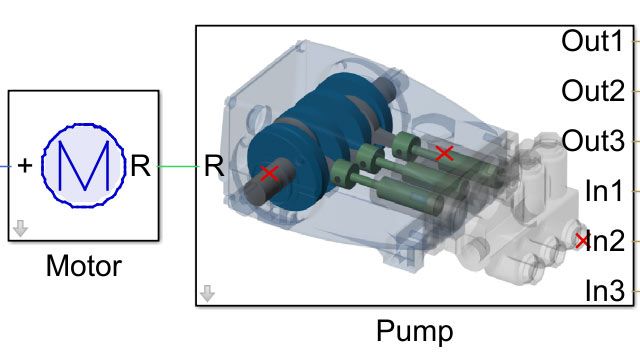

Simscape Fluids offers libraries to model and simulate fluid systems like pumps, valves, actuators, pipelines, and heat exchangers. Use it to design fluid power systems (e.g., loaders, steering, landing gear) and thermal systems (e.g., cooling, lubrication, fuel supply).

Integrate with mechanical, electrical, and thermal components using Simscape. Develop control systems in Simulink, create custom components with the Simscape language, and deploy models with C-code generation for HIL and other environments.

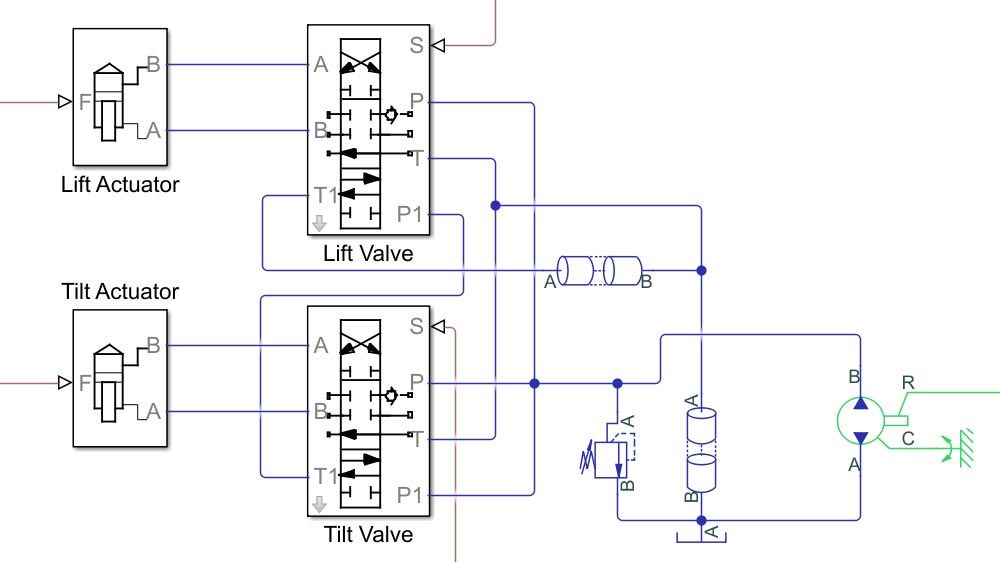

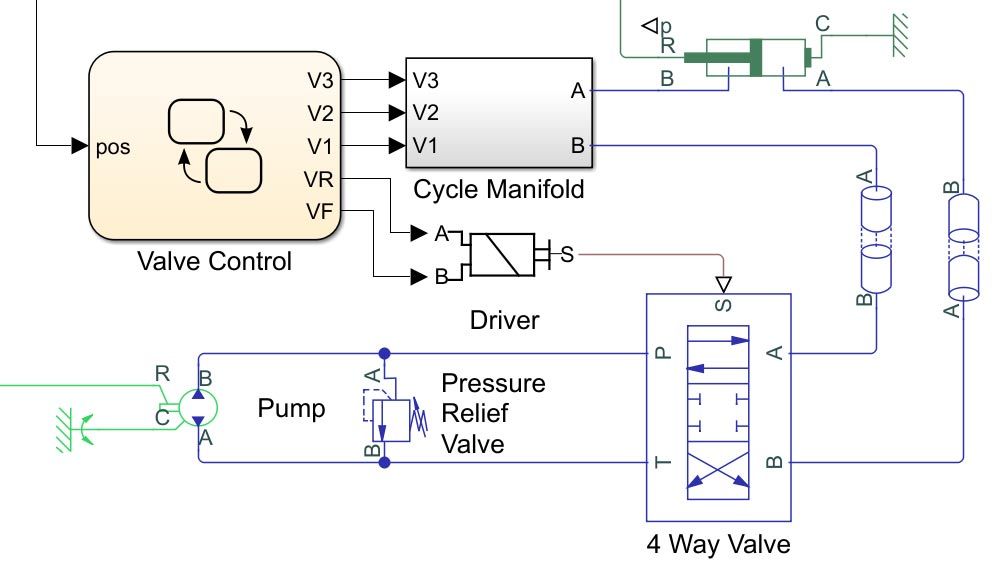

Fluid Power

Model actuation systems for construction, machinery, and aerospace. Analyze thermal effects and develop control algorithms.

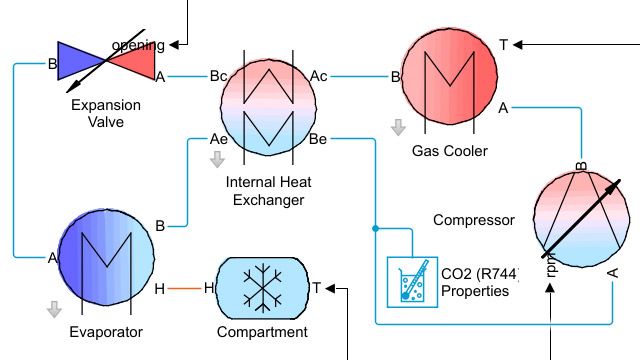

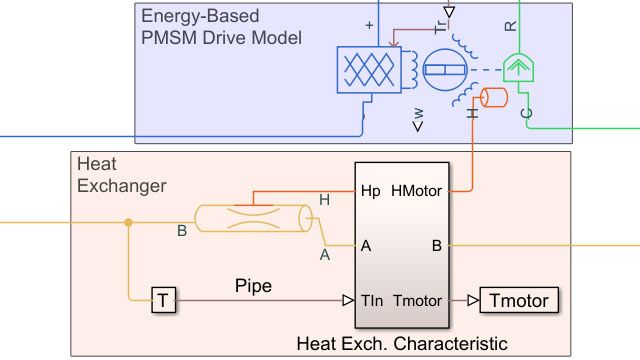

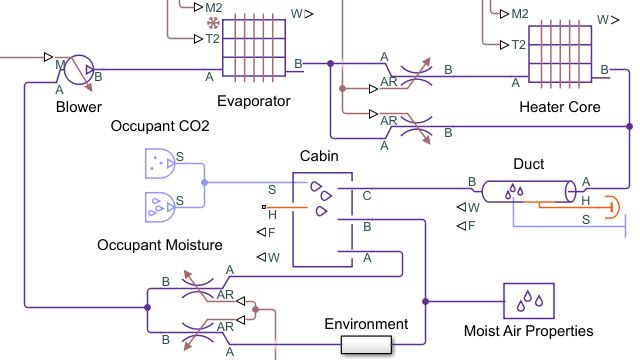

Heating and Cooling

Model thermal management for batteries, vehicles, and buildings. Assess system architecture and refine component requirements.

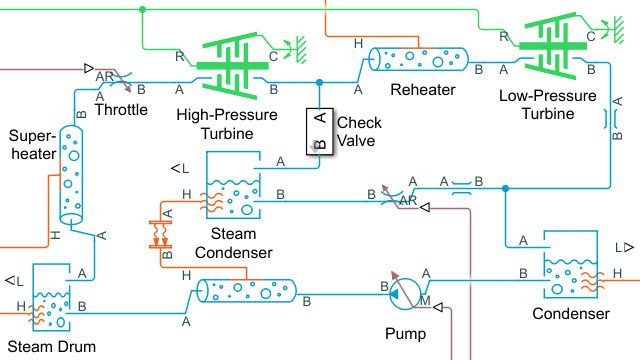

Fluid Transportation

Model fluid flow in tanks, supply networks, and lubrication systems. Automate tests for normal and abnormal conditions.

Predictive Maintenance

Reduce losses and downtime by modeling failures (e.g., leaks, blockages) and creating predictive maintenance algorithms.

Virtual Testing

Verify system behavior in scenarios hard to replicate with hardware, running parallel tests on multicore workstations or clusters.

Model Deployment

Convert Simscape models to C code to test control algorithms and run HIL tests on dSPACE®, Speedgoat, OPAL-RT, and other real-time systems before physical testing.

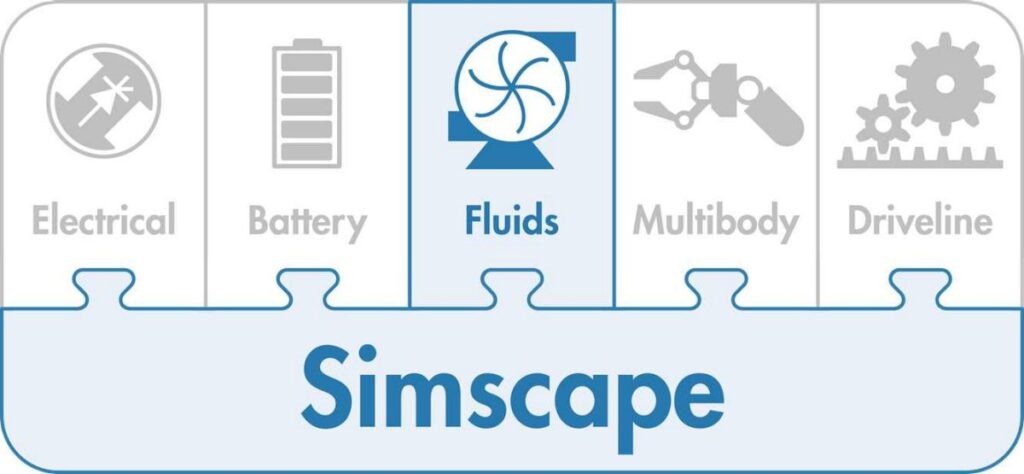

Simscape Platform

Test integration of electrical, thermal, mechanical, hydraulic, and pneumatic systems in a single environment. Identify integration issues and optimize system-level performance.

MATLAB and Simulink

Use MATLAB to automate model assembly, testing, and post-processing, and Simulink to integrate control and hardware design in one environment.

From Research To Production

Simscape models refine requirements, design controls, test embedded systems, and enable digital twins for in-service support.